SHIELDED metal ARC welding

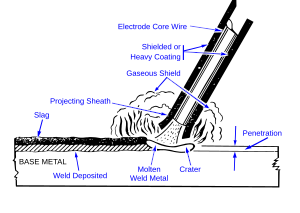

Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding[1] or informally as stick welding, is a manual arc welding process that uses a consumable electrode coated in flux to lay the weld. An electric current, in the form of either alternating current or direct current from a welding power supply, is used to form an electric arc between the electrode and the metals to be joined. As the weld is laid, the flux coating of the electrode disintegrates, giving off vapors that serve as a shielding gas and providing a layer of slag, both of which protect the weld area from atmospheric contamination.

Because of the versatility of the process and the simplicity of its equipment and operation, shielded metal arc welding is one of the world's most popular welding processes. It dominates other welding processes in the maintenance and repair industry, and though flux-cored arc welding is growing in popularity, SMAW continues to be used extensively in the construction of steel structures and in industrial fabrication. The process is used primarily to weld iron and steels (includingstainless steel) but aluminium, nickel and copper alloys can also be welded with this method.

Development

After the discovery of the electric arc in 1800 by Humphry Davy there was little development in electrical welding until Auguste de Méritens developed a carbon arc torch, patented in 1881.[3] Nikolay Benardos developed carbon arc welding, obtaining patents from 1887 showing a rudimentary electrode holder. In 1888 consumable metal electrode was invented by Nikolay Slavyanov. Later in 1890 C. L. Coffin received U.S. Patent 428,459 for his arc welding method that utilized a metal electrode. The process, like SMAW, deposited melted electrode metal into the weld as filler.[4]

Around 1900 A. P. Strohmenger and Oscar Kjellberg released the first coated electrodes. Strohmenger used Clay and lime coating to stabilize the arc, while Kjellberg dipped iron wire into mixtures of carbonates and silicates to coat the electrode.[5] In 1912 Strohmenger released a heavily coated electrode but high cost and complex production methods prevented these early electrodes from gaining popularity. In 1927 the development of an extrusion process reduced the cost of coating electrodes while allowing manufacturers to produce more complex coating mixtures designed for specific applications. In the 1950s manufacturers introduced iron powder into the flux coating, making it possible to increase the welding speed.[6]

In 1938 K. K. Madsen described an automated variation of SMAW, now known as gravity welding. It briefly gained popularity in the 1960s after receiving publicity for its use inJapanese shipyards though today its applications are limited. Another little used variation of the process, known as firecracker welding, was developed around the same time byGeorge Hafergut in Austria.

Operation

To strike the electric arc, the electrode is brought into contact with the workpiece by a very light touch with the electrode to the base metal then is pulled back slightly. This initiates the arc and thus the melting of the workpiece and the consumable electrode, and causes droplets of the electrode to be passed from the electrode to the weld pool. As the electrode melts, the flux covering disintegrates, giving off shielding gases that protect the weld area from oxygen and otheratmospheric gases. In addition, the flux provides molten slag which covers the filler metal as it travels from the electrode to the weld pool. Once part of the weld pool, the slag floats to the surface and protects the weld from contamination as it solidifies. Once hardened, it must be chipped away to reveal the finished weld. As welding progresses and the electrode melts, the welder must periodically stop welding to remove the remaining electrode stub and insert a new electrode into the electrode holder. This activity, combined with chipping away the slag, reduces the amount of time that the welder can spend laying the weld, making SMAW one of the least efficient welding processes. In general, the operator factor, or the percentage of operator's time spent laying weld, is approximately 25%.

The actual welding technique utilized depends on the electrode, the composition of the workpiece, and the position of the joint being welded. The choice of electrode and welding position also determine the welding speed. Flat welds require the least operator skill, and can be done with electrodes that melt quickly but solidify slowly. This permits higher welding speeds. Sloped, vertical or upside-down welding requires more operator skill, and often necessitates the use of an electrode that solidifies quickly to prevent the molten metal from flowing out of the weld pool. However, this generally means that the electrode melts less quickly, thus increasing the time required to lay the weld.[9]

No comments:

Post a Comment